The Science Behind Epoxy Flooring Durability: Why It Outlasts Paint and Sealers in Manchester, CT

If you’ve ever tried painting or sealing your garage or basement floor, you probably know how short-lived the results can be. The color fades, the coating peels, and after a few seasons of salt and snow, you’re right back where you started.

For homeowners and business owners in Manchester, CT, where weather conditions put constant stress on concrete, a long-lasting solution matters. That’s why so many turn to epoxy flooring — not just because it looks great, but because it’s built to last.

But what actually makes epoxy so durable? The answer lies in the chemistry, the installation process, and the way it interacts with your concrete surface.

1. Epoxy Creates a Chemical Bond, Not Just a Surface Coating

Most paints and sealers work by sitting on top of the concrete. They form a thin layer that looks nice for a while, but they don’t truly connect with the surface beneath. Over time, foot traffic, moisture, and temperature swings cause that layer to lift or peel away.

Epoxy works differently. It’s a two-part system made from a resin and a hardener. When mixed, these two components create a chemical reaction that forms a thermoset polymer — a material known for its strength, hardness, and resistance to wear.

Instead of resting on the concrete, epoxy actually bonds to it on a molecular level. This chemical connection makes it far more resistant to damage from heat, moisture, and mechanical stress. Once cured, it doesn’t soften or weaken, even under pressure from vehicles or heavy equipment.

For Manchester homeowners dealing with freeze-thaw cycles, this bond is key. Paint and sealer can’t handle expanding and contracting concrete — but epoxy can.

2. Surface Preparation Makes All the Difference

Durability starts before the first drop of epoxy is even poured. A high-quality installation depends on professional surface preparation, which ensures the epoxy adheres to every pore of the concrete.

At Nutmeg Epoxy, we mechanically grind the floor to open up the concrete’s surface. This step removes dirt, old coatings, and micro-contaminants that could prevent adhesion. By exposing the concrete’s natural texture, the epoxy can penetrate deeply and form a lasting bond.

Skipping this process — as often happens with DIY kits — is one of the main reasons painted or sealed floors fail. Paint and sealers might stick at first, but they can’t anchor into the surface the way epoxy does. That’s why professional preparation and installation make all the difference between a one-year finish and a twenty-year floor.

3. Strength That Comes from Cross-Linking Chemistry

Here’s where the science gets interesting. When epoxy resin and hardener combine, they form cross-linked polymers — a dense, three-dimensional structure of molecules.

This cross-linking gives epoxy its:

High compressive strength: It can handle the weight of vehicles, storage racks, and machinery without cracking.

Abrasion resistance: Dust, tools, and wheels don’t wear it down easily.

Chemical resistance: Oils, solvents, and cleaners can’t penetrate or stain it.

Thermal stability: It stays intact through temperature fluctuations, which is critical in Manchester’s cold winters and humid summers.

These properties make epoxy ideal for both residential and commercial spaces — from home garages to auto shops, warehouses, and showrooms.

Paint and sealers don’t have this kind of molecular structure. They form a simple film, not a reinforced polymer network, which is why they fade and fail much faster.

4. Epoxy Protects Concrete from the Inside Out

Concrete naturally expands, contracts, and absorbs moisture. Over time, these processes lead to cracks, surface wear, and chemical degradation. Epoxy flooring acts as a protective barrier that stops this damage before it starts.

Here’s how:

It seals the surface, preventing water vapor from penetrating the concrete and causing spalling or pitting.

It blocks salt and de-icing chemicals, which are major culprits in concrete deterioration during New England winters.

It resists impact, meaning dropped tools or heavy equipment won’t chip the surface.

Unlike a sealer that wears off after a few seasons, epoxy maintains its integrity year after year. Many of our Manchester clients who installed epoxy five, ten, or even fifteen years ago still have floors that look freshly finished.

5. Long-Term Value That Outlasts Alternatives

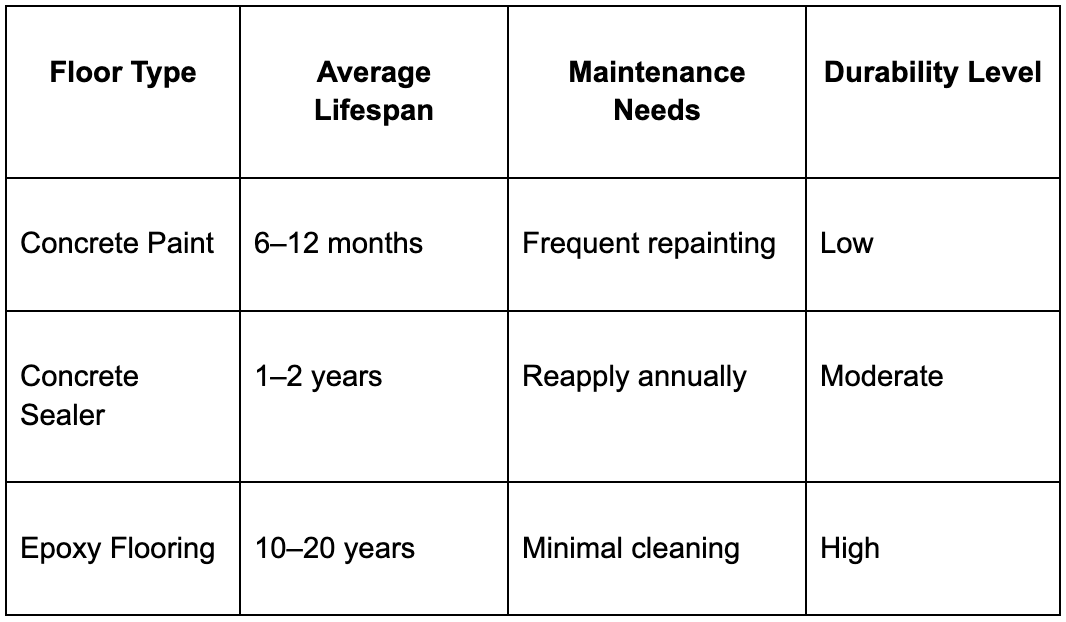

While epoxy may cost more upfront than paint or sealer, it quickly pays for itself through performance and longevity. Consider this comparison:

Epoxy also enhances the look and feel of your space. Whether you choose a decorative flake system for a garage or a metallic finish for a basement, you get both visual appeal and industrial-grade performance.

Over time, it’s not just a better choice for durability — it’s a better investment for your property.

6. Why Manchester Homes and Businesses Rely on Nutmeg Epoxy

Epoxy’s performance depends on the quality of both the product and the installation. At Nutmeg Epoxy, we combine technical expertise with premium-grade materials to create floors that perform in Connecticut’s unique climate.

We don’t just coat your concrete — we engineer it for longevity. From surface prep to final cure, every step is handled with precision to deliver a floor that stands up to moisture, salt, and daily use.

If you’ve been frustrated with peeling paint or short-lived sealers, it’s time to make the upgrade.

Visit our services page to explore your options or contact us to request a free consultation.